Any unit with suspected advancement shall be segregated, its location throughout the batch documented, and examined by a skilled Microbiologist.

Environmental Controls Engineering controls reduce the potential for airborne contamination in workspaces by limiting the amount and dimensions of contaminants from the CSP processing environment. Primary engineering controls are utilised and usually involve horizontal move cleanse benches, vertical circulation clear benches, biological protection cabinets, and barrier isolators. Key environmental Command ought to give no less than ISO Class five good quality of air (see Table one) to which sterile elements and factors of CSPs are directly exposed.

Inspectors have to have documented schooling for the whole process of transferring and analysis of the sample in the ultimate clear container. Lower and significant turbidity contamination shall be A part of this teaching.

Aseptic Approach Crucial functions are carried out by properly trained and experienced personnel within a DCCA employing suitable aseptic procedures explained in a published process (see Prompt Conventional Functioning Treatments). Aseptic strategy is equally applicable to your preparing of sterile sensitizing and chemotoxic brokers. On the other hand, it is critical to acknowledge that extra safety measures need to be utilized to shield the staff as well as the compounding setting through the potential adverse outcomes of such chemotoxic merchandise.

Cleansing and Sanitizing the Workspaces The cleansing, sanitizing, and organizing of the direct and contiguous compounding places (DCCA) is definitely the obligation of skilled operators (pharmacists and specialists) following prepared treatments and is done firstly of every shift. Before compounding is executed, all objects are removed from the DCCA and all surfaces are cleaned of free content and residue from spills, accompanied by an application of a residue-totally free sanitizing agent2 that's remaining on for check here just a time adequate to exert its antimicrobial result.

In advance of planning compounded sterile preparations (CSPs) which means all new employees or when you begin a media-fill testing system should you have not now

That’s why we produced a singular coloration indicator that shifts colours If the filled unit is contaminated, this means you conserve valuable time and maximize accuracy.

The FDA draft Guidance12 clarifies that intervention inside the aseptic manufacturing approach in the course of media; that is definitely to say an interruption of the aseptic barrier does not imply that All those units should be incubated, nevertheless it need to be confident (SOP) that for the duration of schedule manufacturing system this sort of units are turned down.

Sterile powder shall be released to be used only just after prosperous sterility testing and productive progress advertising in media/powder Resolution.

Various facets of barrier isolation and filtered unidirectional airflow in function environment have to be recognized and practiced during the compounding course of action. Guidelines and treatments for sustaining and dealing in the prescribed situations for aseptic processing has to be well prepared, current, maintained, and applied and therefore are determined by the scope and risk levels of the pursuits carried out within the SP compounding operation.

For vial dimension and filling velocity the worst problem is the biggest vial Along with the longest filling time, the widest-neck vial and the smallest vial with the very best velocity.

Upon receipt of every number of the bulk get more info drug substance or excipient useful for CSPs, the individual compounding the planning performs a visible inspection from the good deal for proof of deterioration, other kinds of unacceptable top quality, and Erroneous identification.

Take pleasure in minimal extractable profiles for both of those silicone and TPE tubing to transfer important fluids across approach techniques.

After the ampul is open, the crucial web page of publicity is enormously amplified, developing a pathway with the potential for introduction of glass, fiber, and mud in the fluid contained during the ampul.

Devin Ratray Then & Now!

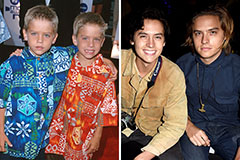

Devin Ratray Then & Now! Dylan and Cole Sprouse Then & Now!

Dylan and Cole Sprouse Then & Now! Bug Hall Then & Now!

Bug Hall Then & Now! Tonya Harding Then & Now!

Tonya Harding Then & Now! Stephen Hawking Then & Now!

Stephen Hawking Then & Now!